EHM Ionizer - Expert In Health Water Solutions – Trusted Alkaline Water Ionizer Manufacturer For Global Brands

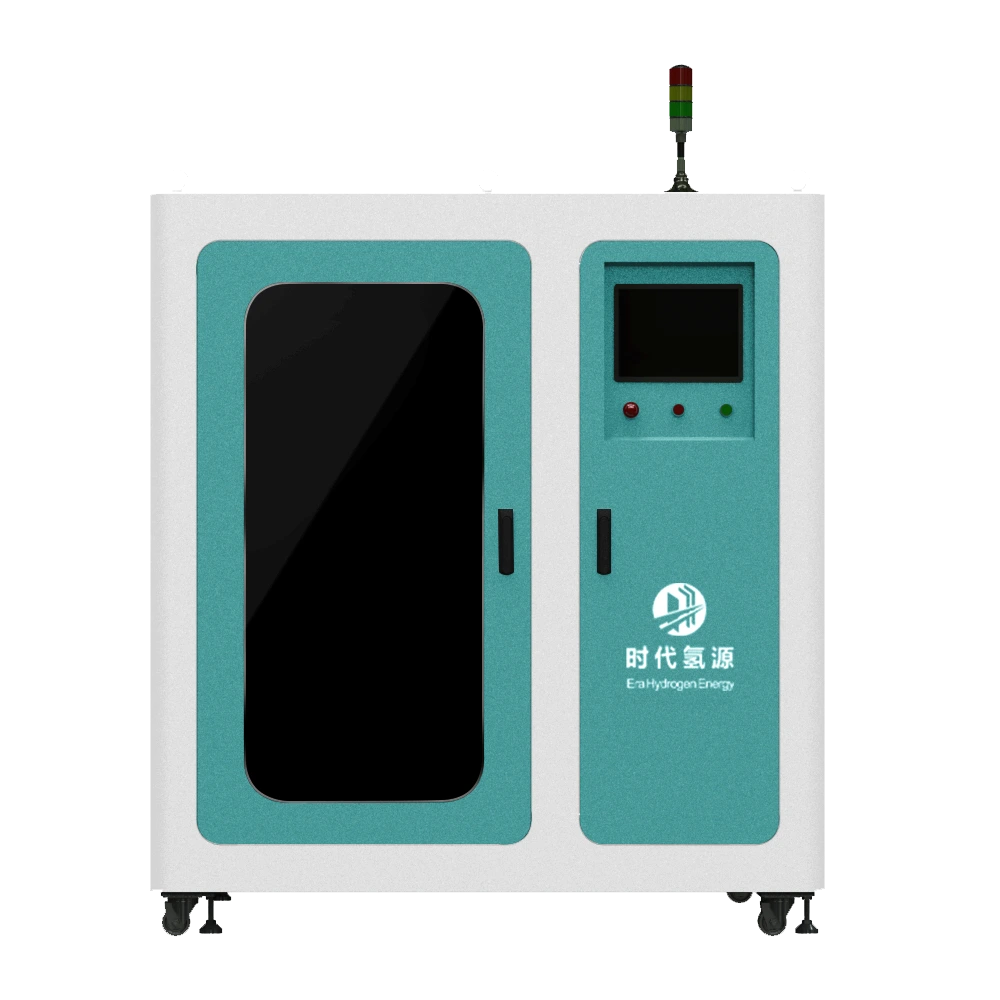

Solar & Wind Green Hydrogen Energy Powered Pure Water Electrolysis PEM Hydrogen Gas Generator Producing 99.9995% High Purity Hydrogen

Green Hydrogen Energy generator /machines

Introduction to the Characteristics of PEM Hydrogen Production Equipment

★ PEM pure water electrolysis hydrogen production (eliminating the addition of alkaline solution and replacing the traditional alkaline solution electrolysis hydrogen production process mode); PEM pure water electrolysis hydrogen production equipment is a high-tech patented product that is lightweight, efficient, energy-saving, safe, and environmentally friendly.

★ PEM pure water electrolysis for hydrogen production: hydrogen with a high purity of 99.995%, non corrosive, and pollution-free; PLC intelligent control, one click start and stop on/off, and high-purity hydrogen gas can be generated within 5 minutes of starting up; Hydrogen pressure (adjustable from 0-3MPa) and hydrogen production can be adjusted from 0 to 100%. The equipment is easy to install, easy to operate, and safe and reliable; Users can remotely monitor device operation data..

★ Product structure characteristics:

Zero polar distance, high activity PEM catalytic electrode

A fully selected, complete, and reliable electrical automatic control system for bipolar multi-element electrolytic cells with excellent mass and heat transfer chemical process performance, electrochemical performance, corrosion resistance, passivation resistance, and other superior properties.

★ Product functional characteristics

Electrolysis of pure water (eliminating the addition of alkaline solution) for hydrogen production, non corrosive, non polluting, and high hydrogen purity;

The unit cell voltage is low, the internal resistance of the electrolytic cell is low and does not generate heat. The replacement cycle of the drying agent is long, and the hydrogen purity is high; The electrolysis current is small, but the gas production is sufficient, and the pressure rise is fast (3-5 minutes);

Stable hydrogen pressure and flow output, and automatic tracking with changes in load gas consumption, automatic protection technology is safe and reliable;

High pressure stabilization accuracy, safe and reliable automatic protection technologies for water shortage, over pressure, water-flushing proof, etc Low noise, low power consumption, high electrolysis efficiency, and good sealing performance.

Specification

PEM hydrogen production equipment parameter & specifications

|

Model Number

|

SDQY-H1

|

SDQY-H5

|

SDQY-H10

|

SDQY-H20

|

|

Max hydrogen output capacity (Nm³/h)

|

1

|

5

|

10

|

20

|

|

Max oxygen output capacity (Nm³/h)

|

0.5

|

2.5

|

5

|

10

|

|

Hydrogen purity(%)

|

≥99.999 (N₂<2ppm:O₂<1ppm)

|

|||

|

Hydrogen output adjustment range

|

0-100

|

|||

|

Output gas pressure(Mpa)

|

0-3(0-100% adjustable)

|

|||

|

Electrolytic water consumption(L/h)

|

1

|

5

|

10

|

20

|

|

Operating temperature

|

≤55

|

|||

|

Electrolytic water temperature(℃)

|

5-45

|

|||

|

Electrolytic water quality requirement

|

Electrical resistivity of water >1MΩ.cm

|

|||

|

Electrolysis power consumption(KW•h/m³)

|

4.5~5.0

|

|||

|

Machine Control

|

PLC

|

|||

|

Power distribution

|

7

|

47

|

88

|

185

|

|

Hydrogen dew point temperature(℃)

|

-65

|

|||

|

Input voltage(V)

|

AC 380V, three phases

|

|||

|

Hydrogen machine measurement L *W * H (mm)

|

L1700*W1100 *H1750

|

L1900*W1300 *H1750

|

L2000*W1300 *H1750

|

L2200*W1300 *H1750

|

5.0

Capacity:

1Nm³/h

Item NO:

SDQY-H1

Brand Name:

SDQY

Lead Time:

40-50 days

Shipping Port:

Guangzhou

Color:

white+light green

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-20-87429918

Moblie: +86 15989278400

E-mail: sale3@ehmglobal.com

WhatsApp: +86 15989278400

Skype: ehmkatherine

Address: No3,Xianke first Road, Huadong town, Huadu District, Guangzhou,China 510890